FAQ Categories

____________

Tips for Builders, Concreters Owners

Indoor Polished Concrete

____________

What types of polished concrete do you offer?

OzGrind offers both a mechanically polished concrete such as the Husqvarna Hiperfloor method and we offer a coating method commonly known as a grind and seal. We also do honed concrete (for exterior), and epoxy flooring.

What is the difference between mechanically polished concrete (MPC) and a grind and seal (G&S)?

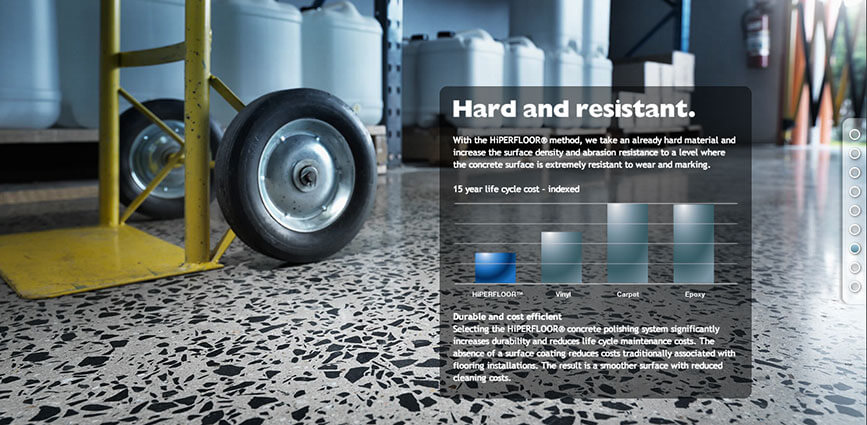

Mechanically polished concrete is for indoors only – it is the true form of polished concrete as it is the concrete itself that is polished and buffed until it shines – there is no topical coating to wear away over time therefore this floor will last you many years. Also, in floors that are mechanically polished like our Husqvarna Hiperfloors or our MPC, the concrete is hardened and densified to up to 10 times its natural strength so it is much less likely to crack. The concrete is also grouted which is a process that fills in the small pin holes and cracks on the surface, so the surface is smooth and very refined – if you run your fingers across the floor it looks and feels like glass. Then the floor undergoes a series of polishes using resins which make the floor smooth, shiny and glossy – you can finish the procedure after just a few polishes so that you end up with a matte finish – or you can continue to polish up to a very high grit for the semi or high gloss finish. The MPC is a very luxurious floor and is very highly recommended by the team at OzGrind.

Click here to see examples of Mechanically Polished Concrete.

A Grind and Seal however can be used for indoors or outdoors – and is a cheaper alternative to the authentic polished concrete and very popular in cafes and restaurants as well as outdoor areas, garages, driveways and homes. This procedure involves grinding the concrete to prepare it for a clear coating of a sealer like a polyurethane or epoxy. The clear coating will protect your concrete and if desired we can use a special grit in the top layer in order to make floors non-slip (ideal for around pools, and any wet areas). The final product still looks similar to the mechanically polished concrete, however it is the sealer that gives the floor an artificial shine – and so like any topical coating, over time this will start to wear and eventually need to be sanded back and re-applied. Sealers will generally last 2-7 years depending on traffic and they are available in a matte, semi-gloss or a high gloss finish.

What is the difference between mechanically polished concrete and honed concrete?

Honed concrete is the matching outdoor finish for the indoor Mechanically Polished Concrete (MPC), as the Honed finish is not quite as refined as the MPC. The Honed finish is grinded to a 60 or 120 grit; this is ideal as it makes it slip resistant. It has a penetrating sealer applied to protect the concrete – this can be done in an invisible sealer (no change to colour of the concrete) or a colour enhanced sealer (which will enhance/darken the concrete). Mechanically Polished Concrete on the other hand is a more complex process that involves densifying and hardening the concrete and then applying resins to polish it up until it shines. This process however can be stopped at a matte finish, or you can continue to polish up to a semi or high gloss.

Is polished concrete slippery?

Generally speaking, it is no more slippery than other hard flooring surfaces. Add water to it though and like any other hard surface it will be slippery. That is why we recommend for outdoor use to do either the Honed finish (matte only) or the Grind and Seal finish (matte or gloss). The Honed finish has inherent non-slip properties, and the Grind & Seal finish can have an anti-slip agent added to the sealer. We can tailor the anti-slip to your needs, meaning that we can add a lot or a little depending on the result you require.

Can you make our polished concrete floor non-slip?

As a general rule Mechanically Polished Concrete is slip resistant – but like many other flooring options it will be slippery when wet. If you need a flooring that is non-slip we would recommend doing a Grind and Seal method of polished concrete or another type of coating like an epoxy. With these flooring options we can add a grit to the top layer which can give a non-slip finish. These are ideal for wet areas, around pools, outdoor areas and other commercial environments.

What type of flooring would you recommend for an industrial setting?

Industrial flooring needs to be hard wearing, usually slip and chemical resistant and durable. With this in mind we would normally recommend an epoxy coating or polished concrete flooring – OzGrind are expert at both and it would be best to give one of the friendly staff a call to learn more.

Can I have polished concrete in wet areas such as shower bases, etc?

Yes it is possible, but we would recommend doing either a grind and seal with a non-slip compound added or if you choose a Hiperfloor, to have a non-slip mat in the wet area. With the grind and seal the topical sealant will be water tight so no water penetrates into the concrete.

Outdoor Polished Concrete

____________

Can you have polished concrete outdoors?

Yes. For outdoors however we would not normally recommend a Mechanically Polished Concrete, as when wet it can be slippery. The alternative for these areas is honed concrete. The reason for this is to provide alternatives for a more slip and UV resistant finish. Honed concrete is ideal for driveways, outdoor areas, concrete around your pool, carports etc.

What types of polished concrete do you offer?

OzGrind offers both a mechanically polished concrete such as the Husqvarna Hiperfloor method and we offer a coating method commonly known as a grind and seal. We also do honed concrete (for exterior), and epoxy flooring.

What is the difference between mechanically polished concrete and honed concrete?

Honed concrete is the matching outdoor finish for the indoor Mechanically Polished Concrete (MPC), as the Honed finish is not quite as refined as the MPC. The Honed finish is grinded to a 60 or 120 grit; this is ideal as it makes it slip resistant. It has a penetrating sealer applied to protect the concrete – this can be done in an invisible sealer (no change to colour of the concrete) or a colour enhanced sealer (which will enhance/darken the concrete). Mechanically Polished Concrete on the other hand is a more complex process that involves densifying and hardening the concrete and then applying resins to polish it up until it shines. This process however can be stopped at a matte finish, or you can continue to polish up to a semi or high gloss.

Is polished concrete slippery?

Generally speaking, it is no more slippery than other hard flooring surfaces. Add water to it though and like any other hard surface it will be slippery. That is why we recommend for outdoor use to do either the Honed finish (matte only) or the Grind and Seal finish (matte or gloss). The Honed finish has inherent non-slip properties, and the Grind & Seal finish can have an anti-slip agent added to the sealer. We can tailor the anti-slip to your needs, meaning that we can add a lot or a little depending on the result you require.

Can you make our polished concrete floor non-slip?

As a general rule Mechanically Polished Concrete is slip resistant – but like many other flooring options it will be slippery when wet. If you need a flooring that is non-slip we would recommend doing a Grind and Seal method of polished concrete or another type of coating like an epoxy. With these flooring options we can add a grit to the top layer which can give a non-slip finish. These are ideal for wet areas, around pools, outdoor areas and other commercial environments.

Concrete Slabs

____________

Can you colour match an existing slab if a new one is poured next to it?

It is possible for us to dye the concrete in both slabs with the same colour – unfortunately the colour uptake by these slabs will not be exactly the same, however this will be the best way to get them looking similar.

Do I have a choice of coloured concrete and aggregate?

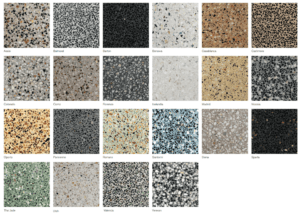

If you are lucky enough to be building a new house or extending, you will most likely be pouring a new slab from scratch. In this case you will be able to choose from the vast range of concrete mixes that are available in your area. OzGrind can polish Hanson, Boral, Holcim or other concrete mixes – the options available for Queensland are shown below. If you are renovating however and using the existing slab, you are more bound by whatever colour cement and aggregate is in your floor – the only real option if you want to change the colour is to use a concrete dye – however most customers are happy with the polished concrete look no matter what colour the cement and stones are.

Can you choose the colour of the polished concrete?

If you want to polish the concrete of an existing slab then you are usually limited to whatever is already in the concrete. Your only real option if you don’t like the colour or the cement and aggregate is to put a colour dye over the top.

If you are pouring a new slab you can choose the colour of your cement and the colour of your stone (aggregate) from a number of concrete suppliers. Some examples of available mixes are below, and here is a virtual tour of our showroom showing real-life samples of available mixes that you can view in close detail. A small number of them are below.

It is important not to underestimate the colour of the cement as this can significantly change the look and the cost of the floor. Below are polished concrete samples using the same stone but changing the colour of the cement:

Do you pour the slab?

No, we generally just do the polishing or grinding, however we do have some concreters that we work closely with and can recommend to you.

Do you have any recommended concreters to pour the slab?

Our recommended concreters are:

Roy Jonkman from RJ Works – 07 3904 7915 – roy@rjworks.com.au (only works directly with builders)

Jesse Stenroos from Luxury Concrete – 0488 165 571 – jesse@luxuryconcrete.com.au

Peter Zocaro from Cemento – 0431 702 245 – info@cementoconcrete.com.au

What about cracks in the concrete?

Part of our grouting procedure can actually fill in small cracks, and if you choose a Hiperfloor the procedure actually hardens the top surface by up to 10 times its natural strength. If any cracks do appear, we can generally repair them. However, it is concrete and you can never guarantee that it won’t crack.

Can I put heating in my slab and still have this polished?

It is not our recommendation to use in-slab heating when polished concrete is the flooring choice. The reason for this is that the heating actually dries out the surface of the slab and sucks up all the densifiers & sealers we use so the surface ends up deteriorating slowly over time. It also makes it more prone to cracking as well as staining because the sealers & densifiers are being absorbed more than usual and are therefore not working properly.

If you/your client is adamant on the in-slab heating, we strongly suggest that after the concrete is fully cured and the project is complete, turn the water temperature up by one degree Celsius per day to prevent the concrete cracking. We also recommend not to exceed 30 degrees Celsius (water temp). Also keeping in mind that we grind off anywhere from 1-6mm, so there needs to be plenty of concrete thickness between the heating cables/pipes/etc and the surface of the slab.

How many days after the slab pour can frames be erected?

To the best of our knowledge, the builder can begin to put internal frames up after a minimum of 3 days, however this is of course subject to the weather, as constant rain or high humidity is likely to prolong the curing time and therefore push this timeframe out.

How long do tradespeople have to avoid walking on the slab after its been poured?

We have been advised 48 hours should pass after pouring that the slab before it is walked on, as this can alter the aggregate placement (push it further down into the slab), creating for bald patches despite grinding down to the furthest possible exposure level.

What type of concrete mix should I use if I want polished concrete flooring?

We recommend contacting your concrete supplier and specifying that the slab is intended for polishing – they should be able to alter the mix to a 32/10/80 mix for minimum/random or full stone exposure polishing. For nil exposure polishing you should pour 40MPA if possible. Most suppliers have their own decorative mixes specifically designed for polishing. If you are using a standard concrete mix, ensure you request fresh water over recycled water to minimise the risk of discolouration in the concrete & finish.

How can footprints in the slab be rectified when the slab is still wet?

If there is a footprint made in the concrete while the slab is still wet this can be rectified by filling it in with concrete mix (containing aggregate). Try not to use just the cream of the screed as this will still result in a bald patch in the shape of a footprint that may still be visible after the floors are polished.

What if my slab wasn’t poured to specification (i.e. lower MPA, cured incorrectly, etc)?

There aren’t many slabs that absolutely cannot be polished, so even if the slab you’ve had poured isn’t to exact specification OzGrind should still be able to grind and polish it. It may just mean that you don’t end up with the exact finish you want – i.e. with lower MPA concrete a nil exposure process may not be achievable.

When pouring stairs for polished concrete – is it best for the concreter to bullnose the stairs or should we leave it for OzGrind?

OzGrind recommend the use of a fillet for all noses of stairs as that way we can finish them in the same stone exposure as the floor otherwise you may end up with full exposure if we are to grind them to put a bevel on them. Also the risers need to be heavily vibrated to settle the slurry against the formwork otherwise you will end up with large aeration holes which can ruin the look of your stairs. The design of you steps is very important – if it has lots of intricate parts or angles, we may not be able to get our hand tools in to grind/polish them so please check or send you step designs to us to look at prior to pouring.

Care and Maintenance

____________

What do you recommend for cleaning a polished concrete floor?

Polished concrete is so easy to maintain! All that is really required is a weekly clean using hot water only or you can add a cleaner specifically made for polished concrete, or any pH neutral all-purpose cleaner. For a daily dust use a dry Micro-Fibre Dust Mop. It is important to ensure spills of any kind are wiped up immediately and not left to soak into the floor.

Will polished concrete fade or discolour over time?

One of the biggest advantages of Honed concrete and Mechanically Polished Concrete is that it will not fade and with proper care will not discolour, however grind and seals or any sealers that don’t have a UV stable coating on the surface will, over time, discolour and may lift, crack or peel.

How do I clean my polished concrete?

The best way to keep your polished concrete in good condition is to use a ph neutral cleaner followed by clean water for spills, otherwise a microfiber mop will get rid of dust.

Can you do repairs to our existing polished concrete floor?

As a general rule yes. Hiperfloor can be repaired easily in small areas, however with a grind and seal entire areas usually need to be done to avoid any differentiating spots.

Will my polished concrete stain if I spill something on it?

Generally speaking it should not. We do use a sealer on all our finishes which prevents staining. However, we do recommend that spills are cleaned up quickly.

How do I maintain my polished concrete?

This depends on what procedure you have done. Grind and seals will need to be resealed every 2-10 years depending on the quality of sealer you have selected, and if you leave it too long you will need to have the floor re-grinded and sealed again. For mechanically polished concrete/Hiperfloors, generally you can just reapply the protective sealer every 10 years.

New Builds and The Process

____________

Do I have a choice of coloured concrete and aggregate?

If you are lucky enough to be building a new house or extending, you will most likely be pouring a new slab from scratch. In this case you will be able to choose from the vast range of concrete mixes that are available in your area. OzGrind can polish Hanson, Boral, Holcim or other concrete mixes – the options available for Queensland are shown below. If you are renovating however and using the existing slab, you are more bound by whatever colour cement and aggregate is in your floor – the only real option if you want to change the colour is to use a concrete dye – however most customers are happy with the polished concrete look no matter what colour the cement and stones are.

If I’m building a new house and pouring a new slab, at what stage is it best to get the concrete polished?

OzGrind should be consulted from the very early stages of the build – we have some information that you can give to your concreter which advises them of the best way to pour the slab for getting the best polished concrete results.

As a general rule the concrete should be cured for 28 days before we actually arrive to do the polish. Then we can do the polish all at once, or in 2 stages. If we are to do the procedure all at once, we do the floors after the frame is up and internals are watertight. If we need to do it in 2 stages, it requires us to do an initial grind and grout prior to the frame being erected and a protective coating being placed over the floor until works have been completed or just before the plaster. We then remove the protective coating and can polish up the floor. It is much better for everyone if we come in after the frame is up, but before the skirting and plaster gets done.

Can you choose the colour of the polished concrete?

If you want to polish the concrete of an existing slab then you are usually limited to whatever is already in the concrete. Your only real option if you don’t like the colour or the cement and aggregate is to put a colour dye over the top.

If you are pouring a new slab you can choose the colour of your cement and the colour of your stone (aggregate) from a number of concrete suppliers. Some examples of available mixes are below, and here is a virtual tour of our showroom showing real-life samples of available mixes that you can view in close detail. A small number of them are below.

It is important not to underestimate the colour of the cement as this can significantly change the look and the cost of the floor. Below are polished concrete samples using the same stone but changing the colour of the cement:

Do you pour the slab?

No, we generally just do the polishing or grinding, however we do have some concreters that we work closely with and can recommend to you.

How soon after the slab has been poured does the concrete grinding/polishing get done?

Generally the answer is after the minimum 28-day curing period, however OzGrind have worked with a product supplier and developed a system where the floors can be completed as early as 7-10 days after the slab is poured. This involves applying a combination of 2 specific products on the day the concrete is poured – please ask one of OzGrind’s office staff for more information!

What stage of the build does the concrete grinding/polishing get done?

If the 7-10 day curing system mentioned above is being done, OzGrind will complete the floors while the slab is still at an open stage (i.e. no framing or any installations) and then a removable floor protective coating will be applied which will stay down till the final stages of the build. If the quick-cure system is not being done, OzGrind will need access to complete the floors after the slab is water tight (i.e. at lock up stage) but prior to the installation of plastering, skirting & cabinetry. If you have a unique build with flush window/door sills or open staircases, suspended hearths, around posts/ slats, etc, please let our office staff know as in some cases we may need to come in prior to these installations for a better finish.

How many days after the slab pour can frames be erected?

To the best of our knowledge, the builder can begin to put internal frames up after a minimum of 3 days, however this is of course subject to the weather, as constant rain or high humidity is likely to prolong the curing time and therefore push this timeframe out.

How long do tradespeople have to avoid walking on the slab after its been poured?

We have been advised 48 hours should pass after pouring that the slab before it is walked on, as this can alter the aggregate placement (push it further down into the slab), creating for bald patches despite grinding down to the furthest possible exposure level.

Can the concrete polishing be done room-by-room so that I can have other trades working in other areas of the floor?

Unfortunately, this is not an option. The polished concrete process is done in a step-by-step process which means that each single step needs to be done over the entire floorspace before the next step can commence. OzGrind will require complete access to all areas being polished when they are onsite ready to begin.

Why can’t the concrete polishing be done after the house has been handed over?

Hand grinders/polishers can only get between 3-6mm away from any finished surface (i.e. skirting, cabinetry, doorjambs) so if the house is at handover and the floors are done, there would be a section along all finished edges that is not reached with the hand tooling and therefore would look unfinished, as well as internal corners would have an area that our circular discs cannot reach. There is also the risk of the tooling damaging the finished fixtures and running our large concrete grinders over the floor up to 16 times means that damage to your new home would be inevitable, as well as the dust that is created throughout the process settling throughout the house – although OzGrind’s machinery is attached to high grade dust extractors, there is always some dust that escapes. OzGrind will not complete floors after handover.

Should we get the floors done before or after floor-to-ceiling glass doors are installed?

We would generally say before as the hand tooling cannot get right up to finished edges and there would be the risk of damage, however this can be assessed case-by-case.

What happens if the floor gets damaged during the build?

If you have chosen a Grind & Seal floor, unfortunately a damaged floor will generally mean the entire floorspace will need to be re-coated/sealed. If you have chosen a Mechanically Polished Concrete floor, these floors can be patch repaired most of the time however it will depend on the location of the damage and how extensive the damage is. If you have chosen OzGrind’s quick-cure process (ref Q2) and have had the removable floor protective coating applied, damages should not occur unless they are very forceful and extensive. Any repairs to damaged floors is chargeable.

Benefits of Polished Concrete

____________

Is polished concrete cold during winter?

Polished Concrete is recognised as being a sustainable and environmentally sensible building product, and this is largely due to its thermal mass properties (which is the ability of the floor to absorb heat and release it slowly). Therefore, in winter if a concrete slab gets warm during the day, it will release this heat slowly at night. Alternatively, in hot weather, if kept shaded after the coolness of the night it will retain that coolness throughout the day. It’s entirely your choice.

Will it feel cold to walk on with bare feet?

Surprisingly NO. Unlike tiles that have a small thermal mass, it can feel much warmer than tiles to touch in cold weather. Due to the size of the slab it is a good insulator and therefore if exposed to sunlight during the day, will absorb the heat and release it slowly at night.

Can you make our polished concrete floor non-slip?

As a general rule Mechanically Polished Concrete is slip resistant – but like many other flooring options it will be slippery when wet. If you need a flooring that is non-slip we would recommend doing a Grind and Seal method of polished concrete or another type of coating like an epoxy. With these flooring options we can add a grit to the top layer which can give a non-slip finish. These are ideal for wet areas, around pools, outdoor areas and other commercial environments.

Does polished concrete really save on lighting costs?

Yes, there have been customers that have stated it has saved them over 50% on electricity bills due to the reflectiveness of the surface.

Is polished concrete durable?

Polished concrete is very durable however the level of durability will depend on what process you choose for your floor. The mechanically polished concrete process is the most durable option for inside as it doesn’t have a coating sitting on the surface which means there is nothing that can be scratched, damaged or worn away by foot traffic. Going for a Grind & Seal does lower the level of durability, however there are particular topical sealers/coatings that are more durable than others so please advise a member of staff what your floor is being used for and they can recommend you a sealer that will be best suited.

Does polished concrete last a long time?

Yes! Mechanically polished concrete can last up to 10-12 years without any major maintenance if it is appropriately installed and maintained during that time. Grind & seal or honed finishes will last this long as well, however will need to be re-sealed every 2-10 years depending on the amount of foot traffic and wear they receive, and what sealer has been used.

What do you recommend for cleaning a polished concrete floor?

Polished concrete is so easy to maintain! All that is really required is a weekly clean using hot water only or you can add a cleaner specifically made for polished concrete, or any pH neutral all-purpose cleaner. For a daily dust use a dry Micro-Fibre Dust Mop. It is important to ensure spills of any kind are wiped up immediately and not left to soak into the floor.

Is polished concrete environmentally friendly?

Yes, often polishing jobs are done on existing concrete which is made from the most common mineral on earth – limestone. Concrete can also be made from waste byproducts and newer concrete may have metal, marble chips or recycled glass which reduces the amount of waste in our environment. Concrete is a very small contributor to greenhouse gases, and will outperform timber, steel, carpet and tiles.

I suffer from allergies and asthma, is polished concrete a good solution for me?

Yes, in fact it is one of the best solutions for you. Polished concrete floors will not support the growth of toxic mould, dirt, pollen or dust mites and therefore are perfect for any sufferers of asthma or other allergies.

About the Polishing Process

____________

How much dust can I expect?

OzGrind use only the best available equipment from Husqvarna to eliminate dust and this includes high-grade Hepa filter vacuum systems attached to the grinding machines. As a result, when doing the main grind there is very little airborne dust produced by the process as approximately 98% of dust is gathered. There is a minimal amount of dust created when using the hand grinders if they are required, so after each step during the procedure the floor is cleaned. There will be some residual dust left after we have completed our job – but you would only expect to see an amount similar to if you had not dusted your home for 4-6 weeks.

How long before I can walk on polished concrete?

One of the advantages of Mechanically Polished Concrete is that once the process is complete, you can walk on the floor straight away – there is no time wasted waiting for a coating to dry. However, you should avoid water being left on the floor or the floor being cleaned with water for 24-72 hours. For an epoxy coating or a grind and seal, we recommend no foot traffic for a period of 24 hours and no heavy traffic (vehicles etc) for a period of 7 days.

How long does concrete polishing take?

The time it takes to polish concrete depends on a few factors – first of course how big the area is, and also if the space is open or if there are lots of small rooms that require hand work, then it depends on which concrete polishing procedure you want – our MPC or Husqvarna Hiperfloor or grind and seal, then how much exposure of stone you want to see, and the level of shine you want. But as an example, a normal double garage for a grind and seal is usually completed in 2-3 days. And for a house that has approximately 100m2 of Hiperfloor allow 5-6 days.

Can you choose the colour of the polished concrete?

If you want to polish the concrete of an existing slab then you are usually limited to whatever is already in the concrete. Your only real option if you don’t like the colour or the cement and aggregate is to put a colour dye over the top.

If you are pouring a new slab you can choose the colour of your cement and the colour of your stone (aggregate) from a number of concrete suppliers. Some examples of available mixes are below, and here is a virtual tour of our showroom showing real-life samples of available mixes that you can view in close detail. A small number of them are below.

It is important not to underestimate the colour of the cement as this can significantly change the look and the cost of the floor. Below are polished concrete samples using the same stone but changing the colour of the cement:

Can you do this after hours?

Work can be performed on weekends and after hours, however surcharges apply.

What can you do about oil stains on a garage floor?

If you want polished concrete on your garage floor we will grind the top coating off first, which will remove some staining. If the oil is still present we can do a procedure called a purge – and we can do this a number of times to bring the oil out of the floor. On most occasions the combination of grinding and purging will remove stains from your garage floor, however we cannot guarantee results. If staining is unable to be removed we would recommend using a solid colour epoxy coating similar to the below image.

Can you make our polished concrete floor non-slip?

As a general rule Mechanically Polished Concrete is slip resistant – but like many other flooring options it will be slippery when wet. If you need a flooring that is non-slip we would recommend doing a Grind and Seal method of polished concrete or another type of coating like an epoxy. With these flooring options we can add a grit to the top layer which can give a non-slip finish. These are ideal for wet areas, around pools, outdoor areas and other commercial environments.

How long does concrete polishing take?

The time it takes to polish concrete depends on a few factors – first of course how big the area is, and also if the space is open or if there are lots of small rooms that require hand work, then it depends on which concrete polishing procedure you want – our MPC or Husqvarna Hiperfloor or grind and seal, then how much exposure of stone you want to see, and the level of shine you want. But as an example, a normal double garage for a grind and seal is usually completed in 2-3 days. And for a house that has approximately 100m2 of Hiperfloor allow 5-6 days.

Can the concrete polishing be done room-by-room so that I can have other trades working in other areas of the floor?

Unfortunately, this is not an option. The polished concrete process is done in a step-by-step process which means that each single step needs to be done over the entire floorspace before the next step can commence. OzGrind will require complete access to all areas being polished when they are onsite ready to begin.

General Questions

____________

What types of polished concrete do you offer?

OzGrind offers both a mechanically polished concrete such as the Husqvarna Hiperfloor method and we offer a coating method commonly known as a grind and seal. We also do honed concrete (for exterior), and epoxy flooring.

Will polished concrete fade or discolour over time?

One of the biggest advantages of Honed concrete and Mechanically Polished Concrete is that it will not fade and with proper care will not discolour, however grind and seals or any sealers that don’t have a UV stable coating on the surface will, over time, discolour and may lift, crack or peel.

What is the difference between mechanically polished concrete (MPC) and a grind and seal (G&S)?

Mechanically polished concrete is for indoors only – it is the true form of polished concrete as it is the concrete itself that is polished and buffed until it shines – there is no topical coating to wear away over time therefore this floor will last you many years. Also, in floors that are mechanically polished like our Husqvarna Hiperfloors or our MPC, the concrete is hardened and densified to up to 10 times its natural strength so it is much less likely to crack. The concrete is also grouted which is a process that fills in the small pin holes and cracks on the surface, so the surface is smooth and very refined – if you run your fingers across the floor it looks and feels like glass. Then the floor undergoes a series of polishes using resins which make the floor smooth, shiny and glossy – you can finish the procedure after just a few polishes so that you end up with a matte finish – or you can continue to polish up to a very high grit for the semi or high gloss finish. The MPC is a very luxurious floor and is very highly recommended by the team at OzGrind.

Click here to see examples of Mechanically Polished Concrete.

A Grind and Seal however can be used for indoors or outdoors – and is a cheaper alternative to the authentic polished concrete and very popular in cafes and restaurants as well as outdoor areas, garages, driveways and homes. This procedure involves grinding the concrete to prepare it for a clear coating of a sealer like a polyurethane or epoxy. The clear coating will protect your concrete and if desired we can use a special grit in the top layer in order to make floors non-slip (ideal for around pools, and any wet areas). The final product still looks similar to the mechanically polished concrete, however it is the sealer that gives the floor an artificial shine – and so like any topical coating, over time this will start to wear and eventually need to be sanded back and re-applied. Sealers will generally last 2-7 years depending on traffic and they are available in a matte, semi-gloss or a high gloss finish.

What is the difference between mechanically polished concrete and honed concrete?

Honed concrete is the matching outdoor finish for the indoor Mechanically Polished Concrete (MPC), as the Honed finish is not quite as refined as the MPC. The Honed finish is grinded to a 60 or 120 grit; this is ideal as it makes it slip resistant. It has a penetrating sealer applied to protect the concrete – this can be done in an invisible sealer (no change to colour of the concrete) or a colour enhanced sealer (which will enhance/darken the concrete). Mechanically Polished Concrete on the other hand is a more complex process that involves densifying and hardening the concrete and then applying resins to polish it up until it shines. This process however can be stopped at a matte finish, or you can continue to polish up to a semi or high gloss.

Can you colour match an existing slab if a new one is poured next to it?

It is possible for us to dye the concrete in both slabs with the same colour – unfortunately the colour uptake by these slabs will not be exactly the same, however this will be the best way to get them looking similar.

Can you do this after hours?

Work can be performed on weekends and after hours, however surcharges apply.

How much dust can I expect?

OzGrind use only the best available equipment from Husqvarna to eliminate dust and this includes high-grade Hepa filter vacuum systems attached to the grinding machines. As a result, when doing the main grind there is very little airborne dust produced by the process as approximately 98% of dust is gathered. There is a minimal amount of dust created when using the hand grinders if they are required, so after each step during the procedure the floor is cleaned. There will be some residual dust left after we have completed our job – but you would only expect to see an amount similar to if you had not dusted your home for 4-6 weeks.

How long before I can walk on polished concrete?

One of the advantages of Mechanically Polished Concrete is that once the process is complete, you can walk on the floor straight away – there is no time wasted waiting for a coating to dry. However, you should avoid water being left on the floor or the floor being cleaned with water for 24-72 hours. For an epoxy coating or a grind and seal, we recommend no foot traffic for a period of 24 hours and no heavy traffic (vehicles etc) for a period of 7 days.

Is polished concrete slippery?

Generally speaking, it is no more slippery than other hard flooring surfaces. Add water to it though and like any other hard surface it will be slippery. That is why we recommend for outdoor use to do either the Honed finish (matte only) or the Grind and Seal finish (matte or gloss). The Honed finish has inherent non-slip properties, and the Grind & Seal finish can have an anti-slip agent added to the sealer. We can tailor the anti-slip to your needs, meaning that we can add a lot or a little depending on the result you require.

Is polished concrete cold during winter?

Polished Concrete is recognised as being a sustainable and environmentally sensible building product, and this is largely due to its thermal mass properties (which is the ability of the floor to absorb heat and release it slowly). Therefore, in winter if a concrete slab gets warm during the day, it will release this heat slowly at night. Alternatively, in hot weather, if kept shaded after the coolness of the night it will retain that coolness throughout the day. It’s entirely your choice.

Will it feel cold to walk on with bare feet?

Surprisingly NO. Unlike tiles that have a small thermal mass, it can feel much warmer than tiles to touch in cold weather. Due to the size of the slab it is a good insulator and therefore if exposed to sunlight during the day, will absorb the heat and release it slowly at night.

What can you do about oil stains on a garage floor?

If you want polished concrete on your garage floor we will grind the top coating off first, which will remove some staining. If the oil is still present we can do a procedure called a purge – and we can do this a number of times to bring the oil out of the floor. On most occasions the combination of grinding and purging will remove stains from your garage floor, however we cannot guarantee results. If staining is unable to be removed we would recommend using a solid colour epoxy coating similar to the below image.

Can you make our polished concrete floor non-slip?

As a general rule Mechanically Polished Concrete is slip resistant – but like many other flooring options it will be slippery when wet. If you need a flooring that is non-slip we would recommend doing a Grind and Seal method of polished concrete or another type of coating like an epoxy. With these flooring options we can add a grit to the top layer which can give a non-slip finish. These are ideal for wet areas, around pools, outdoor areas and other commercial environments.

What type of flooring would you recommend for an industrial setting?

Industrial flooring needs to be hard wearing, usually slip and chemical resistant and durable. With this in mind we would normally recommend an epoxy coating or polished concrete flooring – OzGrind are expert at both and it would be best to give one of the friendly staff a call to learn more.

How long does concrete polishing take?

The time it takes to polish concrete depends on a few factors – first of course how big the area is, and also if the space is open or if there are lots of small rooms that require hand work, then it depends on which concrete polishing procedure you want – our MPC or Husqvarna Hiperfloor or grind and seal, then how much exposure of stone you want to see, and the level of shine you want. But as an example, a normal double garage for a grind and seal is usually completed in 2-3 days. And for a house that has approximately 100m2 of Hiperfloor allow 5-6 days.

Can I have polished concrete in wet areas? Shower bases etc?

Yes it is possible, but we would recommend doing either a grind and seal with a non-slip compound added or if you choose a Hiperfloor, to have a non-slip mat in the wet area. With the grind and seal the topical sealant will be water tight so no water penetrates into the concrete.

Do you pour the slab?

No, we generally just do the polishing or grinding, however we do have some concreters that we work closely with and can recommend to you.

Will my polished concrete stain if I spill something on it?

Generally speaking it should not. We do use a sealer on all our finishes which prevents staining. However, we do recommend that spills are cleaned up quickly.

Can you have polished concrete floors on the second level of a house?

Yes, you can. The main thing to consider is that suspended slabs are generally poured at a higher strength (mPA) than ground floor slabs so if you choose level of stone exposure that is higher than the nil-minimal, you may not get the same result from the upper slabs than you will from the ground floor. Another thing to think about is that normal grinding machines weigh approximately 400kgs so are unable to be lifted up a flights of stairs – crane lifting needs to be considered for upper levels.

Are polished concrete floors loud in an apartment?

It is a common misguided conception of having polished concrete floors is that the acoustic levels are high, when in fact this is not the case. Yes, having polished concrete, tiles, wooden flooring or any other hard surfaced floor in a home is going to create noise, however it is not the flooring that will cause the noise, it is the level of insulation, wall properties and ceiling properties that will determine the amount of noise the floor will create. Polished concrete flooring has been around for a very long time and is an extremely popular choice in new home builds today, and the advantages of having it far outweigh the “disadvantage” of simply being able to hear your feet below as you walk.

Are there risks involved in polished concrete flooring?

Just like any type of flooring, it comes with risks, however as concrete is a natural product there are a few more risks involved – please ask one of our friendly staff for a copy of our general polished concrete floor disclaimer which will run through some of the potential outcomes.

Can the concrete polishing be done room-by-room so that I can have other trades working in other areas of the floor?

Unfortunately, this is not an option. The polished concrete process is done in a step-by-step process which means that each single step needs to be done over the entire floorspace before the next step can commence. OzGrind will require complete access to all areas being polished when they are onsite ready to begin.

Is there somewhere I can see the finishes available to me, to decide on what type of polished concrete I want?

OzGrind’s state of the art showroom is located at 10/29 Links Avenue North, Eagle Farm. Here there is a large range of polished concrete samples for your clients to see and touch, as well as a virtual reality software system which shows all of the available concrete mixes and finishes in a real life setting. The showroom is open Mon-Thurs 9am-5pm and Friday 9am-4pm, however if this time isn’t suitable to your clients, there may be after hours options available depending on staff availability.

Health and Environment

____________

Is polished concrete cold during winter?

Polished Concrete is recognised as being a sustainable and environmentally sensible building product, and this is largely due to its thermal mass properties (which is the ability of the floor to absorb heat and release it slowly). Therefore, in winter if a concrete slab gets warm during the day, it will release this heat slowly at night. Alternatively, in hot weather, if kept shaded after the coolness of the night it will retain that coolness throughout the day. It’s entirely your choice.

Does polished concrete really save on lighting costs?

Yes, there have been customers that have stated it has saved them over 50% on electricity bills due to the reflectiveness of the surface.

Is polished concrete environmentally friendly?

Yes, often polishing jobs are done on existing concrete which is made from the most common mineral on earth – limestone. Concrete can also be made from waste byproducts and newer concrete may have metal, marble chips or recycled glass which reduces the amount of waste in our environment. Concrete is a very small contributor to greenhouse gases, and will outperform timber, steel, carpet and tiles.

I suffer from allergies and asthma, is polished concrete a good solution for me?

Yes, in fact it is one of the best solutions for you. Polished concrete floors will not support the growth of toxic mould, dirt, pollen or dust mites and therefore are perfect for any sufferers of asthma or other allergies.

Can polished concrete be low VOC?

Definitely – there are alternative products that can be used for all of our processes that can provide low VOC options.

Colours and Options

____________

Can you colour match an existing slab if a new one is poured next to it?

It is possible for us to dye the concrete in both slabs with the same colour – unfortunately the colour uptake by these slabs will not be exactly the same, however this will be the best way to get them looking similar.

Do I have a choice of coloured concrete and aggregate?

If you are lucky enough to be building a new house or extending, you will most likely be pouring a new slab from scratch. In this case you will be able to choose from the vast range of concrete mixes that are available in your area. OzGrind can polish Hanson, Boral, Holcim or other concrete mixes – the options available for Queensland are shown below. If you are renovating however and using the existing slab, you are more bound by whatever colour cement and aggregate is in your floor – the only real option if you want to change the colour is to use a concrete dye – however most customers are happy with the polished concrete look no matter what colour the cement and stones are.

What colour choices are available in Epoxy flooring?

Epoxy colours have almost as much colour choice as paint – there are many options available. Please see the below chart.

Can you choose the colour of the polished concrete?

If you want to polish the concrete of an existing slab then you are usually limited to whatever is already in the concrete. Your only real option if you don’t like the colour or the cement and aggregate is to put a colour dye over the top.

If you are pouring a new slab you can choose the colour of your cement and the colour of your stone (aggregate) from a number of concrete suppliers. Some examples of available mixes are below, and here is a virtual tour of our showroom showing real-life samples of available mixes that you can view in close detail. A small number of them are below.

It is important not to underestimate the colour of the cement as this can significantly change the look and the cost of the floor. Below are polished concrete samples using the same stone but changing the colour of the cement:

Pricing

____________

Is polished concrete expensive?

Mechanically polished concrete has a minimal lifetime cost (see below comparison to other flooring options). There are too many options and variables to answer this question in this section. Polished concrete is not a mass-manufactured product that is simply installed, it is a process of grinding and polishing an individual concrete floor. Factors that will affect the end price include how open the floor plan is (so that the grinders and equipment can access all areas easily, otherwise hand work needs to be factored in), the condition of the floor, if it is a new or an existing slab, and how elaborate any decorative options might be, like how much stone exposure you want visible, and what gloss level you want. To get the best idea of how much polished concrete will cost on your floor, it is best to speak to one of the team at OzGrind.

If you would like to get an initial pricing estimate yourself, please feel free to use our Cost Calculator.

What does polished concrete cost?

It is usually worked out on a square meter rate, and price again depends on the procedure – our MPC, our Husqvarna Hiperfloor or grind and seal, level of exposure, condition of the concrete. Any jobs that are under 30m2 usually end up being priced at a job rate rather than a per square meter rate. It is best to ask us for a quote, however, if you would like to get an initial pricing estimate yourself, please feel free to use our Cost Calculator.

Does polished concrete really save on lighting costs?

Yes, there have been customers that have stated it has saved them over 50% on electricity bills due to the reflectiveness of the surface.

Is polished concrete more expensive than tiles?

Of course it will depend on the quality of the tile, however generally we find that we are a similar price or slightly cheaper than a nice quality tile. A lot of people forget that tile pricing is spilt up by a per square metre price for the tile itself, and then another per square metre price for the installation. Polished concrete flooring is priced as a joint supply and install cost.

Why do polished concrete prices vary so much from contractor to contractor?

Some less reputable contractors will only give you one option which is the cheaper option (Grind & Seal) but still charge you the price of a Mechanical Polish so you think you are getting a quality floor but in fact you’re getting a floor that will require ongoing maintenance and, depending on the sealer, that could be as frequently as every year or two. You get what you pay for so if someone is a lot cheaper that the rest, there is most likely a reason (i.e. new to industry and wants to learn on your floor, or employs tradesmen with no experience which leads to us getting calls all the time to come out and rectify the floor, which can turn out costing double as the floor usually needs to be totally redone many times, all at the cost of the builder as they engaged a cheaper contractor to complete works because they didn’t allow enough in their costings for the build). OzGrind has the largest and best showroom around and alongside that we have the admin support which is second to none in the industry.

Why can’t I just base my initial costings off your mid-range price?

Choosing the “mid-range” price to base your costings off will mean that you do not allow enough in your budget for a mechanically polished concrete (MPC) floor. The MPC is the finish that 95-98% of clients building new homes choose, because it is the longer lasting, more durable & hard wearing finish with the most minimal maintenance long-term. The mid-range price of about $80-$90/m2 + GST would only cover you for any Grind & Seal process (cheaper finish) or the lowest range MPC (minimum/random exposure in a matte finish).

Locations

____________

Will you do work in rural and regional areas in Queensland?

OzGrind will perform work in Brisbane, and parts of the Gold Coast & Sunshine Coast at our standard rates. OzGrind is willing to travel for work outside of these areas to rural & regional Queensland, however accommodation and travel surcharges will apply. There is a travel charge for locations between 1 hour to 1.5 hours from the office. And accommodation charges for travel over 1.5 hours.

What areas of Australia do you service?

We service anywhere from the Northern end of Sunshine Coast, all the way down to Northern NSW and inland to West Toowoomba, including everywhere in between. We will also consider travelling further than these locations however, it will depend on the project. Travel & accommodation costs may apply depending on how far your location is from our Eagle Farm office.

Email Us

enquiries@ozgrind.com.au

24 hours 7 days a week!

Call Us

Opening Hours

9am - 4pm Monday - Friday